When analyzing aggregates, ores, coals, and coke in geological or building materials testing laboratories, particle diameter reduction from the original bulk of the field sample is frequently used. Because many of these materials are hard, strong, or brittle, crushing them into smaller pieces is an excellent application for a sturdy, rugged, and long-lasting jaw crusher.

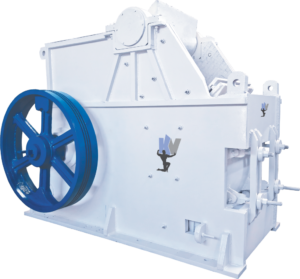

All Best Jaw Crusher work on the same basic principle: two hard-faced heavy plates or jaws smash big particles between them. One motorized jaw initiates an elliptical motion in the opposite direction of a stationary jaw positioned in the frame.

During an operational cycle, the space between the two jaws opens; a particle falls in, the jaws close in on the particle, and it is crushed. The fragmented fragments are crushed further until the particles are tiny enough to fall through the bottom aperture by gravity. Because the jaws are at a slight vertical inclination, particles grow smaller as they go toward the bottom.

The final sample size is controlled by a simple change in the distance between the two jaws. Therefore, the word “ultimate size” might be a little misleading. It refers to the estimated maximum particle size at the end of crushing. However, the size range and distribution might vary greatly depending on the sample’s material characteristics.

The Benefits of a Jaw Crusher

Various characteristics combine to make laboratory jaw crushers the best choice for effectively and efficiently primary crushing hard, brittle, rock-like materials.

- To maximize performance with diverse materials, jaw plates are offered in a range of material kinds.

- Adjustable jaw spacing controls the final sample size and adjusts for wear.

- Reversible jaw plates increase the time between replacements.

- However, the tried-and-true technique yields reliable, reproducible outcomes.

- Jaw crushers are designed for safe, easy operation and maintenance.

Who is the Best Jaw Crusher Machine Manufacturer in Indore?

Working with a knowledgeable material handling solutions partner, such as Jaw Crusher Gold Crush, is the best way to locate the right jaw crushers for your unique application.

- Jaw Crusher Gold Crush has been regarded as one of the top producers and suppliers of Material handling Equipment for more than two decades. Single Toggle Jaw Crusher, Double Toggle Oil Based Jaw Crusher, Double Toggle Grease Based Jaw Crusher, Conveyor Idler, Jaw Plates, and more goods are available from us. The goods meet the needs of the iron and steel, coal, power, and chemical sectors, to mention a few. We employ high-quality raw materials in our production process, resulting in high-quality products.

Jaw Crusher Gold Crush is the Best Manufacturer of Jaw Crushers Machine in Indore. We are the best way to locate the right jaw crushers for your unique application.

Contact Us: +91-8085309838

Email Us: kvmetal76@gmail.com